Packaging

Blister Packing :

The blister packing is developed for holding and displaying products in a clear plastic case, sealed to a sheet of cardboard. Blister packs eliminate the need for additional carton packing, thereby reducing the cost of packaging.

Benefits of blister packing :

- Due to removable cardboard at back one can use the packing multiple times without damaging the package. This helps to keep product safe in packaging for long time after using it for multiple times.

- Plastic blister container provides good visual appearance and texturally pleasing experience to the product.

- Due to the plastic front, it allows consumers to view the product before purchasing which provides reassurance of product quality and aesthetics.

- The individualised compartment of product shape restricts the movement of product within the packaging. This design protects products from the damages during transportation.

Half Blister Packing :

The half blister packing is developed for holding and displaying products in a clear plastic case sealed to a sheet of cardboard. In this packing the usable part of product is sandwiched between plastic and cardboard & remaining portion or the portion which doesn’t affects the product performance remains outside the pack. Blister packs eliminate the need for additional carton packing, thereby reducing the cost of packaging. Half blister packaging also, reduces the usage of excess packing material and requirement of storage space.

Benefits of half blister packing :

- Due to removable cardboard at back one can use the packing multiple times without damaging the package. This helps to keep product safe in packaging for long time after using it for multiple times.

- Plastic blister container provides good visual appearance and texturally pleasing experience to the product.

- Due to the plastic front, it allows consumers to view the product before purchasing which provides reassurance of product quality and aesthetics.

- The individualised compartment of product shape restricts the movement of product within the packaging. This design protects the products from the damages during transportation.

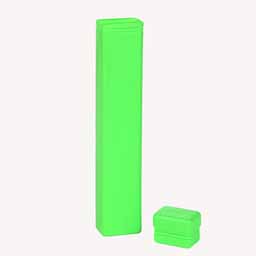

HDPE Box :

HDPE is a recyclable thermoplastic mostly used to produce many types of bottles and containers. Due to its stiffness and high tensile strength it is used for producing packaging as well. JK wraps all its files in wax paper/ VCI paper/ laminates/ PVC pouches etc. and then put them into the HDPE boxes. These HDPE boxes are available in multiple colour options and can be produced in custom colour too.

Benefits of HDPE box packing :

- HDPE provides resistance to many solvents, chemicals, grease and oils, therefore the oil provided for rustproofing of files does not reacts with HDPE box and prevents damage to the packaging

- Due to its sturdiness it doesn’t get damaged due to sharp corners of internal products or external objects.

- High impact resistance of these HDPE boxes prevents them from breaking due to impacts during the transit.

- These HDPE Boxes are easy to carry due to their light weight and does not add much extra weight to the product’s gross weight.

- These boxes comes with tight fitted lid on it so that one can use this packing for storage of files while in regular use.

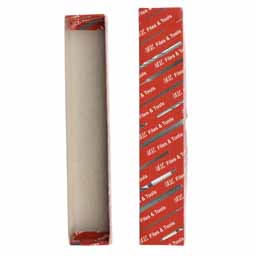

Flip Top Cardboard Box :

It is called Flip box or tube box. This Box has a structure where in one end is permanently closed and other is provided with up and down buckle connection with destructive tear-opening. It is very easy to unwrap and it cannot be reused once opened due to its tear-off opening mechanism. It is mainly used as an anti-counterfeiting packaging.

Benefits of Flip Top Cardboard Box :

- Made up of high quality cardboard, therefore provides sufficient safety to the products from getting damaged.

- It helps to prevent moisture from infiltrating to the product and prevents it from rusting.

- As it is lightweight, it does not add too much to the gross weight of the product and reduces over all transportation cost.

- As it cannot be reused once the top of the box gets tear-off opened, it helps preventing reuse of the packaging and in turn prevents counter-feiting of the product by fraud manufacturers.

Printed Cardboard Box :

It is a standard cardboard box with flap opening provided on both the sides of the box. This Box is reusable. It is manufactured from high quality and high strength cardboard which prevents the product from normal damages.

Benefits of printed cardboard Box :

- It helps to prevent moisture from infiltrating the product and prevents it from rusting.

- Due to its lightweight, it does not add too much to the gross weight of the product and reduces over all transportation cost.

Plain Top Bottom Cardboard Box :

It is a standard cardboard Box. Commonly used in packaging of various products. It consists of top and bottom pieces that fit over each other. These boxes are available in plain white colour as well as multicolour print options.

Benefits of Plain Top Bottom Cardboard Box :

- It helps to prevent moisture from infiltrating the product and prevents it from rusting.

- Due to its lightweight, it does not add too much to the gross weight of the product and reduces over all transportation cost.

Skin Carded packaging :

Skin carded packaging (also known as skin packs), is a carded packaging which keeps the product contained within a piece of paperboard. A thin sheet of see-through plastic covers the product and paperboard.

In this type of packaging the plastic is made soft using heat and then it is placed over the product on the paperboard backer and vacuum sealed to ensure a tight fit. The plastic covering the product takes the shape of the product.

Benefits of Skin carded packaging :

- It offers a more secure and tight packaging to the product.

- It prevents product contamination.

- Provides product visibility and tamper evidence.